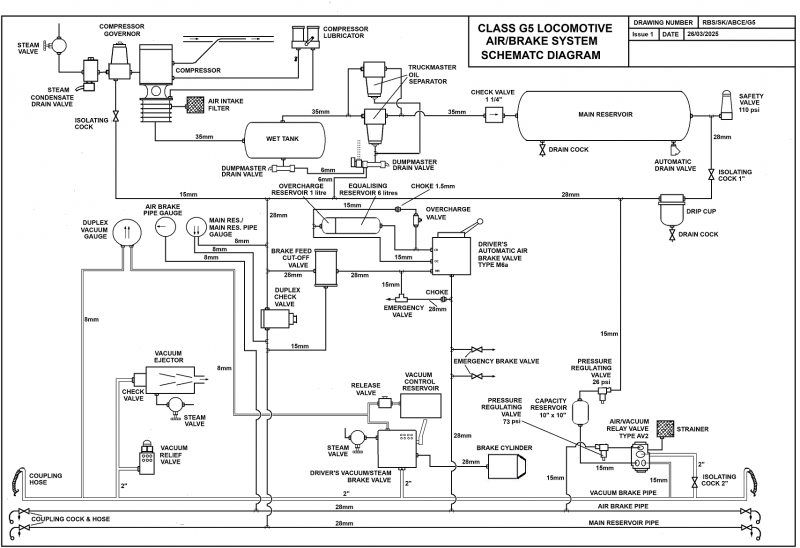

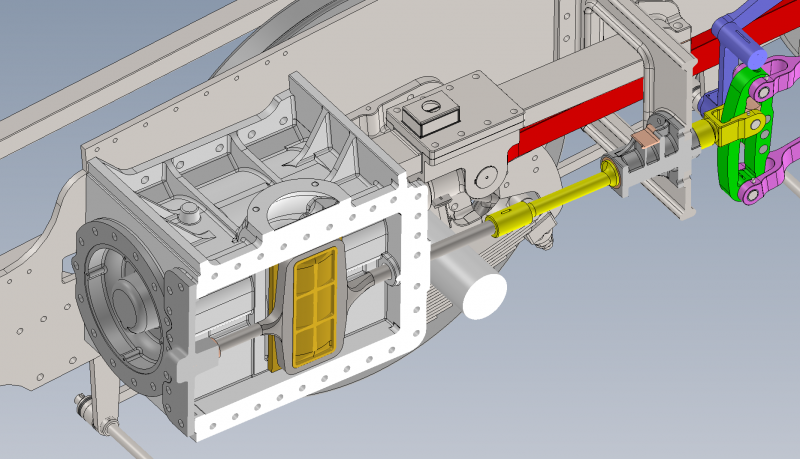

While we are making the effort to get the locomotive moving as soon as possible, it is important that it can stop. So, we invited Keith Nicholson of Railway Braking Services Ltd to the unit for a chat.

The initial consultation was to discuss requirements for steam, air and vacuum braking. Keith, very quickly, has put together a brake system schematic for the G5.

Alan Parkin, seen on the left in the photo, can then workout where we will put it all! Keith, with his years of experience, is also marvel at sourcing the required components.

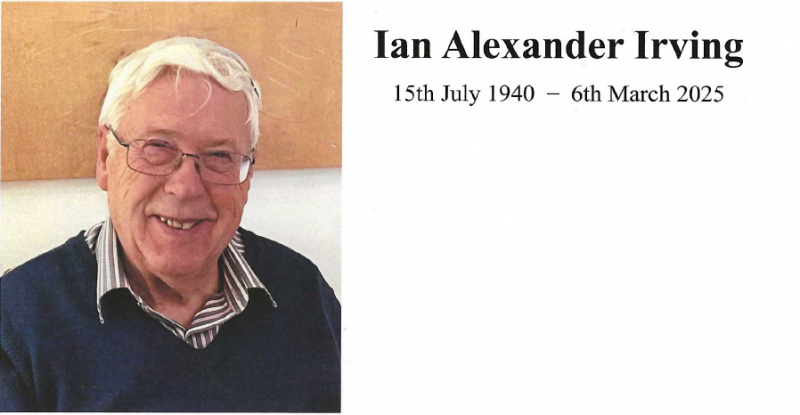

We are very sad to report the death on Ian Irving. Ian, as well as the many things he did for his local community, was a founder member of the Class G5 Company.

Without Ian's enthusiasm and support we wouldn't be where we all today. He will be sadly missed.

Our first open day of 2025. Thank you to those who attended on a fairly cold March day. They were able to see the progress. As well as the rearranged unit, which gives us more working space for the larger components.

Good to see some long time supporters and a few new faces.

The year has moved on quickly, Saturday 28th September saw the AGMs of the Company and the Friends. 'The Stute' in Shildon were again our gracious hosts. We had a good turnout for the meeting.

Thank you to all who made the effort to come. Apologies were passed on at the meeting for those who advised they were unable to attend.

We were very pleased to have been invited by Darlington Model Railway Club to participate in their exhibition at the Oakleaf sports centre in Newton Aycliffe. Both days were busy. Met some familiar faces, plus a many new people interested in the project. We are hoping for a busy open day in October, where they can see our progress.

A big thank you to the organisers and Darlington Model Railway Club for inviting us. It's in the diary for next year. Hopefully see you there!

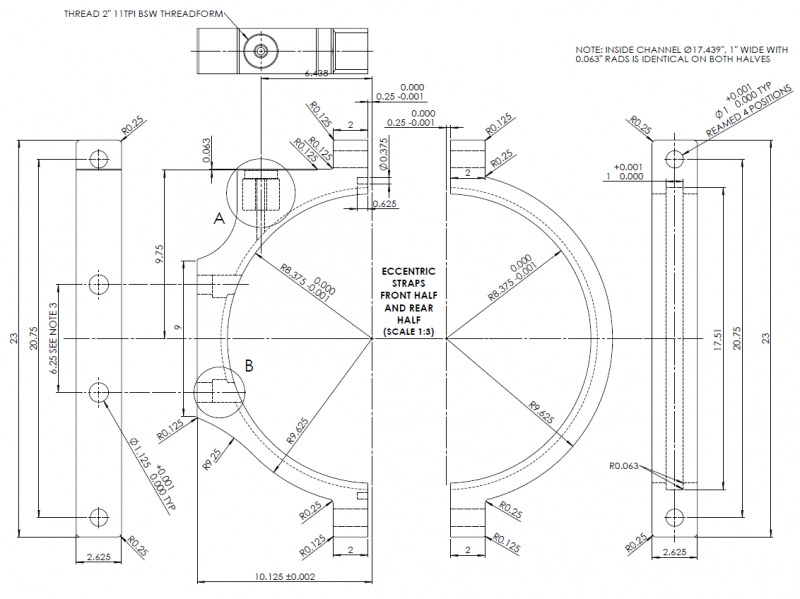

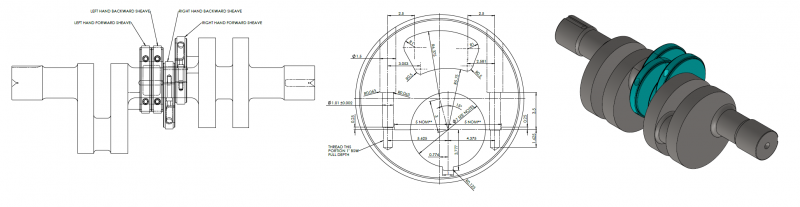

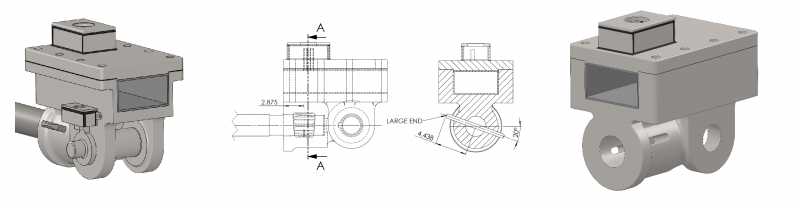

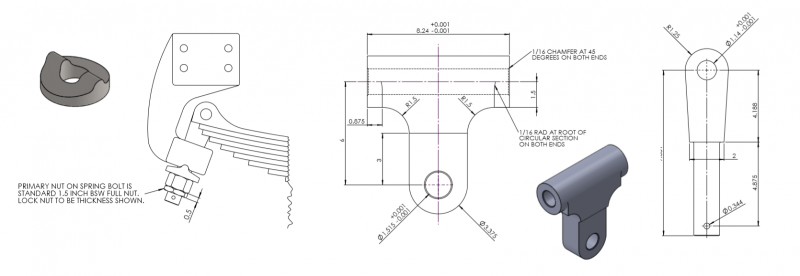

Thanks to the generosity of a shareholder, we have been able to complete the design work on the four eccentric straps. An order, for them, has been placed with Daniela Works Ltd and we anticipate them taking approximately three months to manufacture.

The straps also require a liner made from LG4 leaded gunmetal bronze. Because these will need to be a perfect circle, the best manufacturing method is centrifugal or spin casting. Daniela Works will also be supplies these to ensure a correct fit.

We have had a number of successful opens days so far this year. Some familiar faces, catching up on the progress of the project, and some new faces, visiting for the first time. We even had a reunion of ex-employees.

Why not come down for a visit as an individual or a group, you will receive a warm welcome!

We have been busy laying the rails. First step was cutting to fit.

Then some manual labour to set-up the rail extensions at the front of the locomotive.

Note some people working and some people watching. The next stage was rolling the bogie.

This hasn't turned a wheel since we moved into the unit. Luckily, it took a gentle push and it started moving. Then a simple matter of laying the rest of the rails and rolling the bogie back into position. All done!

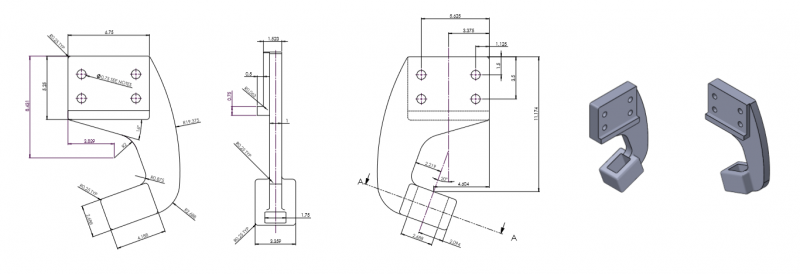

While Daniela Filova is working on the final machining of the cylinder block and fitting of the valve cover, it is an ideal time to work on the design of the slide valves spindles, glands, valve rods and bushes.

Alan Parkin, our CAD designer, has recently visited the unit and is working closely with Daniela to ensure the CAD drawings will enable us to manufacture parts so they fit with the minimum of work.

At our last open day, attended by a number of brave souls, one of our long term supported made a very generous donation of his 3¼" gauge wooden model G5 to the project.

Seen here with Phil and Rob Sowden (new supporter), Jim Pringle, Barry Wilkinson (long term shareholder) and Norman Raine (Friends' company secretary). The model was built from scratch by a friend of Jim, who was a time served pattern maker.

Nearly like the song from 'The Snowman', the frames have been raised up so we can relay the rails on sleepers.

We need to do this so we can position the lifting jacks in place when required. We can also 'roll' the bogie, which hasn't moved for a number of years. Mike can also finish paining in some of the areas that were hard to reach.

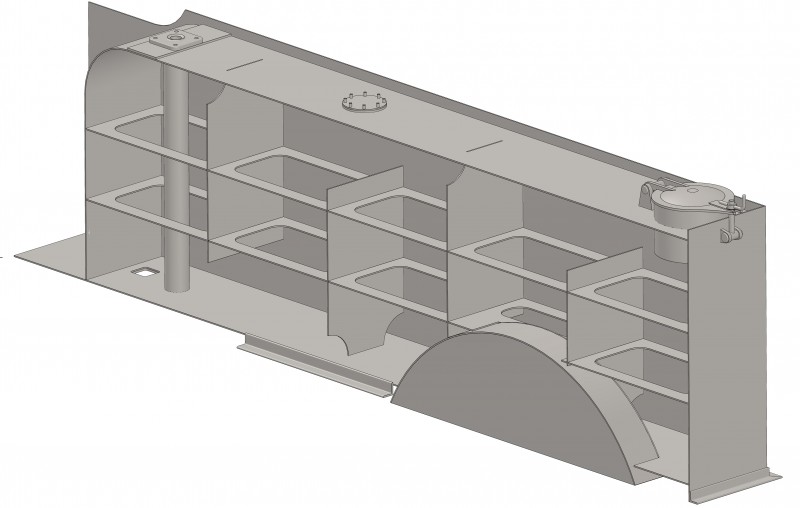

Launched with the last Gazette, the '10 Gallon Fund', to raise £25,000 to enable us to have the two side tanks manufactured, has had a great initial response. We are happy to announce that an order has been placed with Northern Steam Engineering for these.

The lead time is relatively long and we can expect delivery in the Spring of 2024. We still require more funds for this. Please help by going to the 'Construction Funding' page and subscribe to the fund.

The Model Centre (TMC), Beck Hole, have received their first batch of Bachmann oo gauge models.

See the link below for the limited edition 1759 NER lined green: -

https://www.themodelcentre.com/35-251z

There are a number of different liveries, with many options on weathering.

See Hornby Magazine review on Youtube https://www.youtube.com/

As you will be aware, we have had issues with one of the driving wheel and have now placed an order with William Cook for a replacement. The wheel pattern has been dusted off again.

While we wait for this, a decision was made to get all the components back from South Devon, so for a short period of time the 'Crank-axle' is back at the unit. Come to an open day to see it.

Once the wheel is finished, we will send them back to SDR for assembly of the trailing crank-axle.

Saturday 4th of March was a cold day, but everyone who attended our 1st open day of this year received a warm welcome.

We were lucky enough to be visited by the Friends of Stockton and Darlington Railway to see the progress (our unit is just off the route of S&DR, towards the Brusselton Incline). The group then went onto Shildon Railway Institute for the book launch of 'It wasn't Rocket Science' written by Mike Norman. A true history of Timothy Hackworth.

If you are part of a group who would be interested in a visit, please email g5locomotive@gmail.com to arrange.

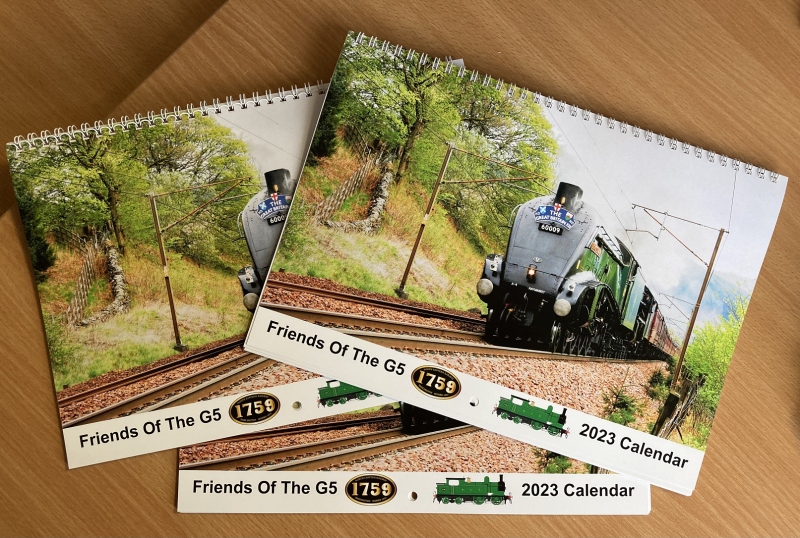

The 2023 Friends of the G5 calendar is now available priced at £5 plus p&p.

A very kind shareholder has produced & printed the calendars, featuring NER & LNER locomotives, at his own expense. Therefore all of the proceeds of the sales will go towards the locomotive build.

They can be purchased and sent by post by emailing: friends@g5locomotiveltd.com

September saw the 70th anniversary of the last passenger service from Rothbury. G5 locomotive, No.67341, had the honour of pulling the final train. (Photograph courtesy of NERA archive)

We were invited by Rothbury and Coquet History Society to attend their October meeting to commemorate the date. A talk was given by Revd. Dr. Stephen Platten on 'The Last Train'. Tim Taylor did a quick presentation on the history of G5s and the new build project. We then presented Rob Walker with a Blyth 52F shedplate donated to us by Jim Pringle, a G5 supporter, who's uncle and father were both drivers on the line.

We went to see the Steam Gala at NYMR on Sunday, and were luck to be allowed onto the footplate, by Chris Cubitt, of 'Peggy' No.29 0-6-2T.

Chris, who was a fireman on G5s, reckons the arrangement in the cab is very similar to a G5! (except the coffee cup). It will be great to see the G5 running there.

Thank you to everyone who made the effort to visit us for our September open day and saw the latest progress. Why not visit for our October open day for even more updates.

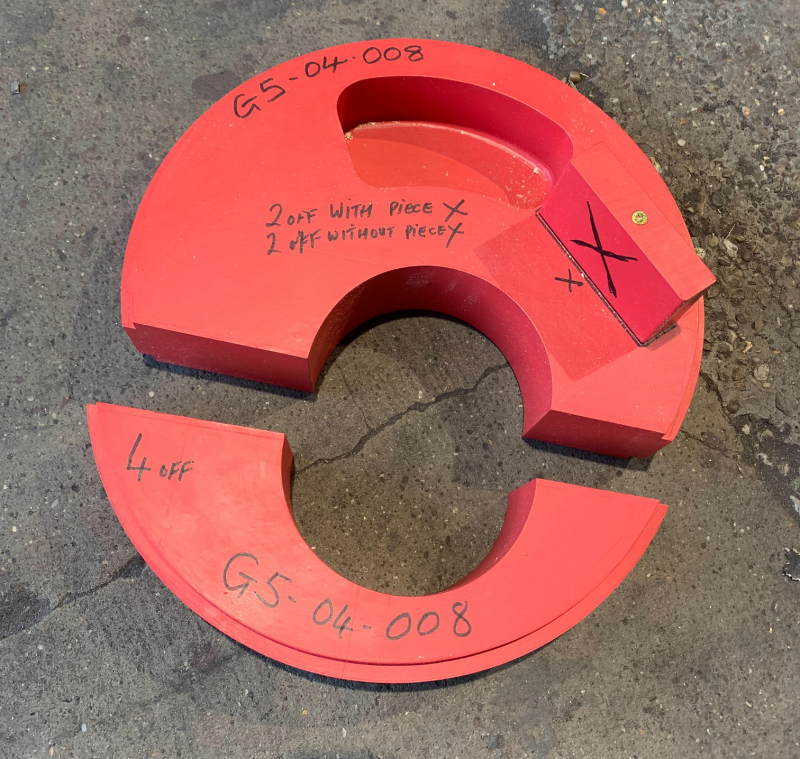

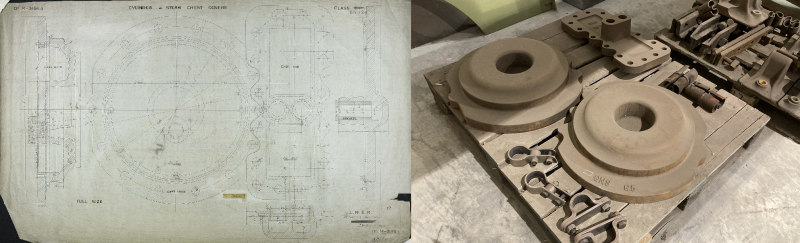

The pattern for the eccentric sheaves have been made.

We will check the dimension for machining, then go ahead with the casting. (photo courtesy of Mark Sutton)

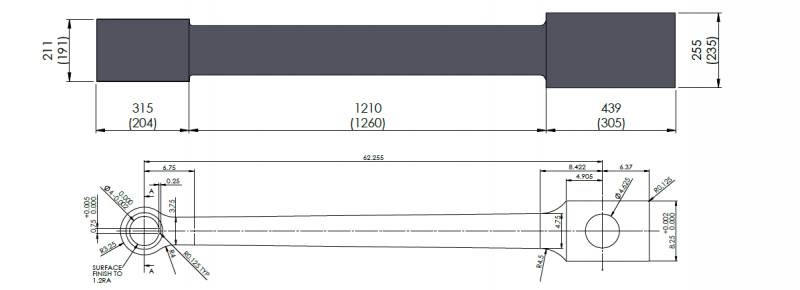

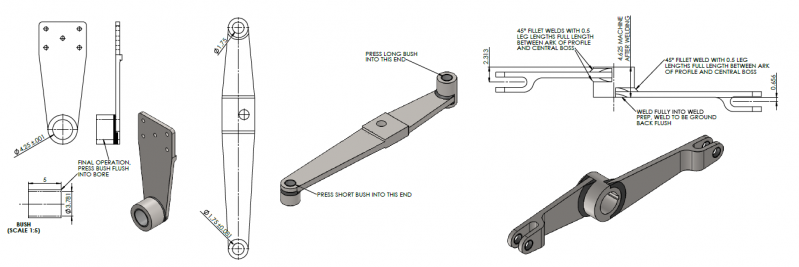

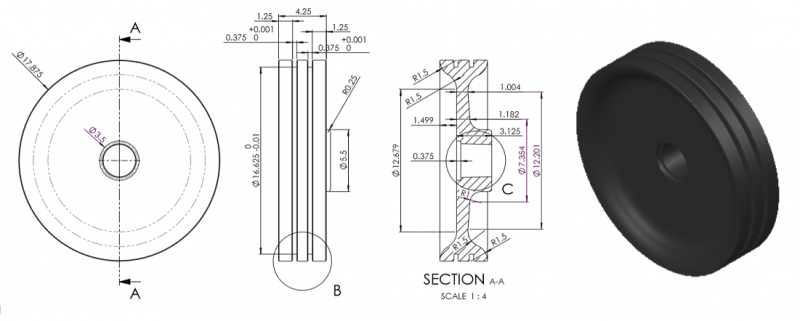

Thanks to the initial up take of the 'Get Connected' fund (see Construction Funding page), we have placed an order for the forgings, which will be machined to form the connecting rods. Below are drawing for the forging and the final machined rod. Lead time for these is roughly 8 - 10 weeks.

An order has also been placed, with Sutton Castings Ltd, for the four eccentric sheaves.

This will require a pattern to made from this the sheaves will be cast. These will then be machined to fit the crank axle.

On the afternoon of Saturday 7th May, after our normal open day, we have a visit from Tanfield Railway Friends. 25 plus member had a tour of the unit and an update of our progress so far, also a glimpse of things to come.

It was great to have a group of like minded people coming to see what we are up to. We are both working together to preserve steam heritage, particularly in the North East of England.

If you are part of a group who would like a visit, please email g5locomotive@gmail.com and we can book a time convenient for both parties.

We have had some good news, Daniela Filová, recently of A1/P2 trust, has set-up her own engineering company. It is in the same block of units, where we are, but just around the corner. This means we have a well equipped machine shop on our doorstep. Daniela Works, her company, has been commissioned to machine the two cylinder covers and the steam chest covers. Also to machine a full set of studs, for when we fit them.

Daniela set to work straight away to sort out a price for the work.

We were lucky enough to be invited to the 12th annual model railway exhibition held at the Youth Centre in Newton Ayclliffe. Arrange by the Rotary Club the show, which has missed the last two years, was well attended. We saw a lot of new faces who will hopefully visit our unit on one of our open days held on the 1st Saturday of the month 10am to 1pm.

We even had a visit from Sandra Haigh, the Mayor of Great Aycliffe.

Thanks to the invitation from Nigel Wright (one of our shareholders), Norman Raine recently attended a new working group who's shared objective is to develop technical and project management solutions in delivering locomotives fir for UK mainline running. The founder members are B17 Steam Locomotive Trust, Class G5 Steam Locomotive Company Ltd, General Steam Navigation Locomotive Restoration Society, P2 Steam Locomotive Company Ltd and Standard Steam Locomotive Company (72010 Hengist)

The inaugural meeting was held at CTL Seal Ltd, Sheffield, and focused on risk assessment and certification. It is anticipated that the meeting will be held every six months.

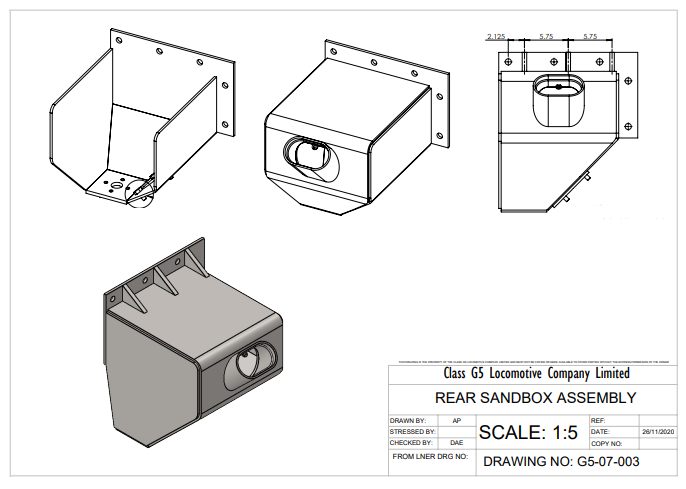

The order for the rear sandboxes has been placed, thanks to contributions to Superfriends.

We will have them early in the new year.

We held the companies AGM on Sunday 21st November at Shildon's Railway Institute. It was well attended, as always. The Railway Institute is full of history in the heart of the North East railway heritage.

There were many events happening across the North East this weekend to celebrate 196th years of the Stockton and Darlington Railway. We opened for an extra day on Sunday. I was great to see some new faces, those who couldn't attend on our Saturday open days. We will do the same again next year.

After a year without open days, we very quickly arrived at our second one. Here you can see Brian waiting to greet the many enthusiastic visitors who were waiting for us to open. If you look closely you will notice the new arrived and painted main brake shaft.

On the same day we also had a stand at the 'Little Big Meeting' held in Hackworth Park, Shildon. A mini celebration of mining and railways in the North East. We shared a tent with the Brusselton Incline Group and Friends of the Stockton and Darlington Railway. The event was well attended and the weather held off despite the forecast.

We held our first open day, for over a year, on Saturday 3rd July. We had a very busy day from the off. Thank you to everyone who attended. Many, who were existing supporters, eager to see the progress (and the quality of Mike's paintwork). We also had a number of people, who very new to the project, which is always nice.

Those who visited were lucky enough to see the pistons and just arrived crosshead bodies in the flesh!

The Class G5 Locomotive Company haven't let Coronavirius spoil their plans to acknowledge David Elliott's 70th Birthday on the 1st of March (St David's Day). Tim Taylor, G5 Company Secretary, presented a G5 cake, at the unit, to David in recognition of this milestone birthday and his involvement with the build,

David has been involved as the project's design engineer from the outset and his knowledge, skill and enthusiasm have been to the build's success.

Mike Wood, Chairman of the Class G5, said "It would have been fabulous to surprise David with a large gathering of supporters and volunteers at the unit in Shildon, but unfortunately lockdown scuppered those plans. We couldn't let this special birthday pass, so Tim stepped in to present the cake to David."

Following on from the success of Cash for Crossheads, allowing us to purchase the crossheads, we have launched the 'Put the brakes on' fund to enable us to buy the brake components. See Construction Funding page.

.............................................................................................................................................................

Please see 'Building Progress' for the latest update.

................................................................................................................................................

Due to the initial uptake of the 'Cash for Crossheads' fundraising scheme (go to the construction funding page, we are now in a position to place the order for the crossheads.

They are on a six month lead time. We still need to complete the fund so we can order the gudgeon pins, oil boxes, wedges and to machine the slots in the piston rods.

................................................................................................................................................

Our March Open Day and first of 2020 was well attended. We welcomed some regular visitors, some who hadn't been for a while and some who hadn't been before. Thank you to all who attended.

................................................................................................................................................

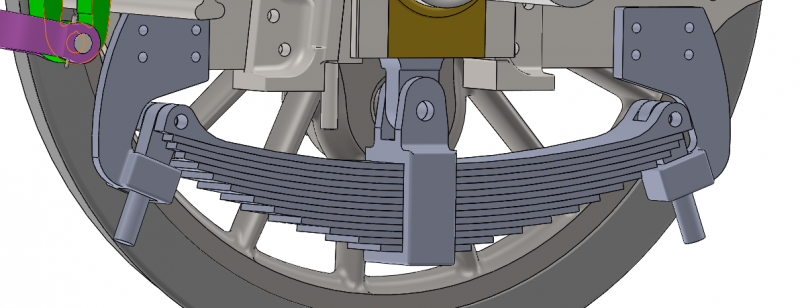

As the next goal of the project is a 'rolling chassis' (we have the main spring and spring hangers) the next parts we require are the Spring Links and Spring Hanger Links, so an order has been placed with Northview Engineering in Darlington for these.

................................................................................................................................................

Another Year, another AGM (and a cold one!) Hard to believe, but a year has passed since the last AGM. Thank you to all who attended, particularly those who travelled far to get here. It's great to get support for a North East locomotive from all corners of Britain.

The Friends' meeting was followed by the Shareholders' AGM. Mike Wood, our chairman, thanked those who attended, updated everyone of the progress over the last 12 months and expressed our deep gratitude to every person who has supported the project.

................................................................................................................................................

We have had a brilliant response to the piston plea (See Fund Raising page) and are now in the position to place the order for the pistons.

The order for forging blank and machining has been placed with Stephenson Engineering, who machined the coupling rods. Lead-time is about 16 week.

...............................................................................................................................................

Thanks to generous contribution to the piston plea we have now placed an order for the piston rods. Delivery is expected within 6 weeks.

We are also in a position where we can order the pistons and have requested quotation on forging and machining of the pistons. If you would like to contribute to the piston plea, please go to the fundraising page and down load the application form.

...............................................................................................................................................

Now that we have the main Axle Springs we need the components to hang them from the frame and take another step closer towards a rolling chassis, so we have ordered tye spring hangers (Drawing below)

...............................................................................................................................................

This year's Conference took place on Saturday 29th June. Over 40 supporters of the project visited the unit on the afternoon for another of David Elliott's, project design engineer, fascinating technical presentation. The guest saw some of the new items just arrived in the unit (see build progress).

We then moved onto the Mecure Kings Hotel in Darlington for an evening meal and an informative and illuminatin presentation from Richard Barber, Trustee of the Armstrong Trust, on the life, social history and unfortunate demise of Darlington's North Road Locomotive Works.

Congratulations to Paul Flint who won the blind auction for the V2 worksplate on the evening. Thank you to David Barraclough for donating this.

...............................................................................................................................................

Orders have been placed for the following: -

Piano Front

Front Sandboxes / Splashers

Main Axle Springs

...............................................................................................................................................

Saturday 6th October saw the 11th Annual General Meeting of the Class G5 Locomotive Company Ltd. We were joined by over 40 Shareholders and Friends. Roger Womersley, one of the founder member of the company, stepped down from the role of Treasurer, which he has held since the start of the company in 2007. We thank him for efforts, enthusiasm and more importantly keeping the books straight. Steve Raine, one of the directors, was elected to take his place.

The AGM was followed by a fascinating film of Alan Tingate's reminiscences of his days as a fireman at Blaydon Shed.

...............................................................................................................................................

On Sunday 12th August Aycliffe & District Bus Preservation Society ran a number of return trips from the Locomotion Museum, Shildon, to our unit. Thanks to all who visited.

...............................................................................................................................................

Saturday 7th July saw the 3rd annual G5 Conference. At 3pm we had about 40 Shareholders and Friends at the unit for a superb technical presentation for David Elliott, our design engineer, on the progress and difficulties of the build. We then moved onto the Mercure King's Hotel in Darlington for an evening meal and a fascinating presentation from David Dunn, who has access to and is archiving the JW Armstrong collection (he currently has nears 450,000 photographs). David's presentation was of G5s in steam and being scrapped.

...............................................................................................................................................

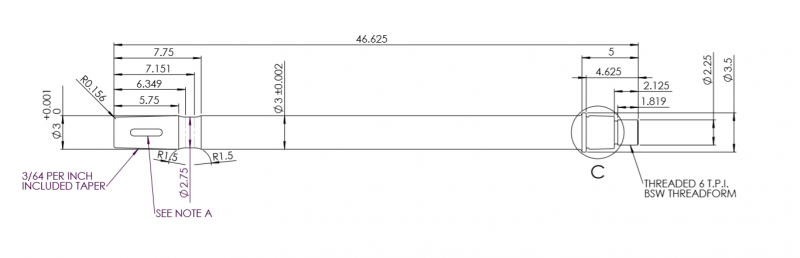

Lincoln Crankshaft have now completed the rough machining of the crankshaft. It will now have a slot cut out of between the webs to provide a test sample to comply with testing requirements. After this it will be ultrasonically tested for flaws in the forging and then the final machining will take place.

Many thanks to all the friends who have visited our open days throughout the year.

Hope to see you again next year.

Have a look at the gallery to see the progress with the crank axle.

PRESS RELEASE Thursday 4th May 2017

ORDER PLACED FOR THE LAST EXPENSIVE COMPONENT

THE CRANK AXLE ORDER HAS BEEN PLACED

Following on from a meeting on 19th April 2017 , which was attended by representatives of G5LC, Project Design Engineer David Elliott, Ricardo Rail, Mott MacDonald and Lincoln Crankshafts & Machine, the order has been placed to forge the crank axle.

This is a major step forward for the project as this is the last expensive component to be purchased, meaning the project is now around two-thirds complete. As crank axles are a safety critical item, this has taken around 12 months for all parties to be happy and clear about how the crank axle is to be produced.

David Elliott, Project Design Engineer commented: “The ordering of the crank axle for the new G5 locomotive represents a major step forward in the design engineering work required to permit main line running. The study work undertaken by Mott MacDonald has demonstrated that the minor improvements made to the design of the original G5 crank axle, and using a modern chrome molybdenum forging steel will produce a crank axle which complies with the modern national railway standards for axle design.

“This says a lot about the quality of the original design which dates from 1896!

“This milestone has been achieved with willing assistance from LC&M at Lincoln who have been contracted to forge and machine the new axle, and our assessment party, Ricardo Rail, who are monitoring and guiding us through the process of achieving design approval for eventual main line running.”

PRESS RELEASE Thursday 8th December 2016

MOTT MACDONALD APPOINTED FOR CRANK AXLE CALCULATIONS

Modern rail vehicles (and this includes new build steam locomotives) now require certification using the Common Safety Method for Risk Assessment (CSM-RA) - a pan European standard. There are 3 basic routes through CSM-RA:

1) Following national or international design standards

2) Using existing design where it has proved to be satisfactory and where the assumptions used in that design are known

3) Calculating and demonstrating that the components are strong enough for the job

The G5 class in common with many locomotives designed in the late 19th and early 20th century has its cylinders mounted between the frames. This necessitates having a crank axle to transmit the drive from the connecting rods to the wheels. By the time that today’s design standards were written, steam had been withdrawn and no modern rail vehicles have crank axles. Whilst the original design is believed to have worked satisfactorily, we do not have any of the calculations or assumptions used by the draughtsman in 1896! This precludes the use of the 2nd method.

We therefore need to undertake calculations and modelling to assess whether the existing crank axle design meets modern requirements. Given the complex combinations of forces that are experienced by crank axles, this would severely stretch the capacity of a piece of paper and a calculator!

Mott MacDonald Limited have considerable experience in rail vehicle analysis. In supporting the G5 project, they are now embarking on their second steam locomotive crank axle analysis project. Bob Harris Mott MacDonald Engineer commented:

Mott MacDonald use ANSYS Finite Element Software to do the work. The ANSYS software produces a very convincing picture of the stress in every part of the axle so it is vitally important that we define the correct inputs! The stress levels can then be used to work out how often, as well as where, the axle needs to be checked that it hasn’t started cracking, since they are critical to the safety of the G5.

In order to make this analysis as accurate as possible we need accurate figures for the weight of the components and as a starting point we have weighed the leading wheelset in order to accurately assess the weight of the crank axle wheelset. Have a look at the gallery to see pictures of this operation carried out by David Elliot.

Richard Maughan, CEO, The G5 Locomotive Company Limited commented:

“This is possibly one of our most significant milestones so far. It has stretched our financial commitment to the project, but Mott MacDonald are the renowned experts in crankshaft stress analysis and we will obtain the certification we require with their engagement. There is light at the end of the tunnel now for project completion”

The Crank Axle Degree Fund was launched with a target of 360 pledges of £100.00 – thus providing us with enough funds to purchase the crank axle; so far, we are over 50% of the way there.

To become a “Graduate” of The Crank Axle Degree Fund, purchase shares or become a Super-Friend, please call 07764 304210 or email g5locomotive @gmail.com

November 5th went with a bang as usual and with it went out last open day of 2016; although don't forget that we can make special arrangements for shareholders to view the current stage of construction by contacting one of the team.

We will be back next year in March to start a new programme of Open Days.

We still have our limited edition O Gauge Ace trains G5 models for sale - just contact one of the team - they could make an exciting Christmas Present.

Hope to see you all again next year when we will have more exciting news of the progress in the con

New Year News (3rd Jan 2016)

Following on from the success of having the front wheelset returned from South Devon the Company have placed orders for:-

The machining and fitting of the motion bracket to the main frames.

The machining of the axle box housings

The casting of the Phosphor Bronze bearings for the axle boxes

The manufacture of the smokebox

The design drawings for the footplate along the sides of the frames

And the purchase of a reconditioned Wakefield Lubricator

All of these are currently funded through the sale of shares, very generous sponsorships and a significant contribution via G5 Superfriends

THE FRONT WHEELSET IS NOW IN THE UNIT AT SHILDON (14. 12. 15)

THE OTHER TWO DRIVING WHEELS AND PATTERN

HAVE BEEN RETURNED FROM BORO FOUNDRY

SEE PICTURES

November 7th was our last open day for 2015, we expect to restart the open days at the beginning of March following the same pattern so the first Saturday in March should be it.

The front wheelset has not been returned yet although it is now complete, we are waiting for some machining to be completed on the two main driving wheels still a Borough foundry. When this is complete we have a contract for the collection of the front wheelset from South Devon and the two other driving wheels and wheel patterns from Boro Foundry. We expect all this to be back in the unit in Shildon some time in December 2015. The transport will be at the hauliers discretion in order to minimise costs.

Update on G5 Move

All of the components have been moved to the new unit except got the boiler which we expect to be in the new unit in the next few days. Have a look at the pictures to see the latest situation. 25.3.15

On the Move

From the 1st of February the G5 will be moving to new premises. The new unit is opposite the previous one at RRNE in Shildon.

This is the last phase in the construction of the locomotive and will see the frames turned over ready to accommodate the bogie and wheel assemblies. The new unit has much more space and will allow us to work on the construction and store all the assembled parts safely.

October 2014

The cylinder blocks are now finally in position and the front buffer beam bolted into position. All the horn guides are now fully machined and bolted into position. The key ways have been machined in the leading driving wheels and we are awaiting transport to take the tyres and front wheels to Devon for assembly.

Follow links from building progress to see pictures of the cylinder blocks in position

Work is progressing with the fitting of the cylinders, the machining of the cylinder blocks is complete. The bolts need some final machining before the cylinder blocks and front horn blocks are fixed into position. The second hand right steam valve has been reconditioned and is now in full working order. The left hand steam valve which was bought new has been uprated with new stainless steel spindles to make them both the same specification.

Last Year's Events

The G5 Locomotion has received a lot of media attention lately from the local radio stations, The Northern Echo and the BBC. The latest coverage is can be viewed below:

The BBC - Click Here

The Northern Echo - Click Here

Following the increasing media attention, our May open day was our most successful open day since the boiler launch.

From this open day we gained many new friends of the G5 and potential new investors visited Shildon to see the latest progress.

Someone who came to our 1st open day even uploaded their own video! Please Click Here

In the Beginning… Click Here

Summary of Latest News: 2013

Success at RRNEL

Saturday saw the sun shining at Rail Restorations North East for the launch of the newly completed G5 Boiler. The largest standard gauge steam engine boiler to be built in this country for the last 45 years.

BOILER LAUNCH, SATURDAY 12TH MAY 2012 AT 10.00 am, AT RAIL RESTORATIONS NORTH EAST, SHILDON

Be there to see the completed boiler and view progress on the assembly of the frames

Posted 25.04 12

Barrow Hill

The team had a very successful 4 days at Barrow Hill on April 13,14,15 & 16. We hope you were able to come along and meet us for all the latest up to date information. We certainly enjoyed the Steam Gala and were very encouraged by the amount of interest shown and the financial support received. Many thanks to those of you who made it and keep watching out for more information - we hope to have regular open days soon at RRNEL so that you can come along and see the progress for yourself.

Progress at RRNEL

Following the relocation of all the completed components to RRNEL at Shildon work has commenced at a pace on the construction. The main frames have been set up on stands and the buffer beam ends, crosspieces and castings aligned for assembly.

Watch this space about news of the completion of the boiler.

Picture by S. Fox, The frames are being assembled upside down to make access to the work space much easier.