...........................................................................................................................

...........................................................................................................................The cylinder block has been returned to the frame. It didn't take as long as expected!

We can the start re-assembling the front end of the locomotive or the coming months.

The fabrication of the two side tanks by Northern Steam is now well underway. There was a slight delay as the initial material received was not the correct quality. This has now been replaced.

The left hand tank is nearly complete.

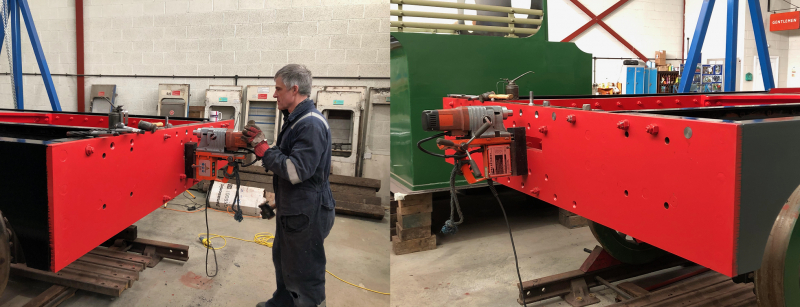

After a few delays, work has started on putting the cylinder block back into the frames.

All the hole are cleaned, reamed and countersunk to the correct depth, to ensure correct bolt fitment.

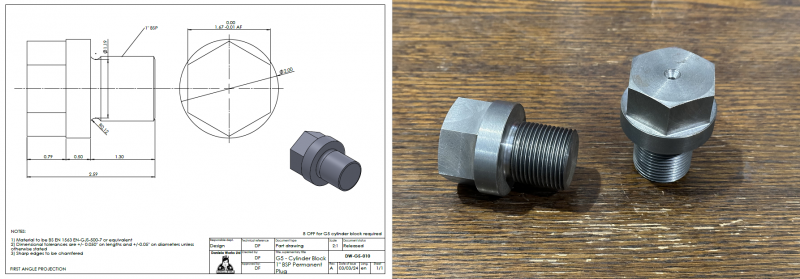

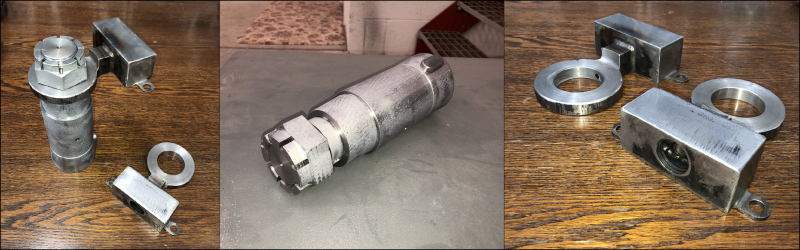

We also have the block's permanent plugs, these blank of the core plus holes.

From drawing to end product.

The crank-axle, two tyres and wheel have been collected from the unit and have started their journey to Buckfastleigh, Devon

On the way south, they will drop into William Cook to collect 'wheel No 4' and then onto South Devon railway to have the wheel-set assembled.

William Cook have sent 'wheel No 4' to ADA Heavy Machining for initial machining. It has been returned to Cooks for some check measurements and is now back at ADA for final machining. The keyway will be cut shortly.

We have spoken to Rob at South Devon Railway Engineering, who has been very accommodating with his time scale, and hope to book us in for assembly in March.

The replacement wheel has be cast by William Cook. This has gone through testing process and passed. In view of the difficulties other new build projects have had with the casting of their wheels, we took the prudent decision to commission William Cook to carry out a rigorous physical examination to confirm the integrity of the other three wheels.

I am very happy to report they passed easily and we now have the necessary certification. The new wheel will soon be undergoing the final proof machining including cutting the keyway.

Daniela has successfully completed the move into her new unit (next door to ours). This now means that she can complete the final machining work on our cylinder block.

Once the work on the block is done, we can reassemble the front end of the locomotive; front buffer beam, smoke-box and chimney can be refitted. We can then start to fit the front running boards, front splashers/sand-boxes and front buffers.

As you can see, thanks to Daniela careful work, the machining of the front cylinder covers is complete.

They will now be removed to facilitate the final machining of the cylinder block. This will make the re-assembly process a lot easier and quicker.

The rear sandboxes have now been fitted. Thanks to Ian Matthews for help with this.

They went on relatively easily, with only a small amount of 'fitting' work to be done.

The difficult job of painting inside of the sandboxes is now complete. well done John!

We hope to have these fitted for our 1st open day of the year on 4th March. Why not come down?

John Askwith has been busy again trying to get as much pre-work and painting done before the temperature drops too much.

When the machined cylinder block is returned to its position in the frame, it will need to have metal to metal contact, so the shape of the block has been taped out ready for the paint removal. John is also working on preparing the cab sides and front. This is the second coat of etched primer after the cleaning up. The next step will be three coats of undercoat and three coats of green gloss. Then we have preparation work for spraying red oxide paint to the insides of the rear sandboxes. These should be easier that the front sandboxes as thy have two large access ports.

Daniela has been busy working on the cylinder block. 44 studs have been manufactured for the front cylinder cover and valve chest cover, these require final machining. It is very handy having around the corner.

You can see the block has also has a rebate machined on the front (and rear) to accept the modified smokebox. There is still a bit of work to do on the block before it is fitted back in the frame.

See the full video

https://www.danielaworks.co.uk/post/class-g5-locomotive-cylinder-block

The smokebox and chimney are now stunning matt black, having been treated to a coat of heat proof paint.

Work has started on fitting the front cylinder covers and steam chest cover. We have decided to remove the block to make this easier and carry out the final machining at the same time. We started by removing the front buffer beam and obviously the smokebox and chimney. These will be painted with heat proof matt black paint, in preparation for the reassembly.

The block was then slung and lifted out of the frame. It's now ready for Daniela to start work.

Another £1,000 worth of bolts.

On the left and middle - Countersunk and domed bolts for the front buffer beam with philidas nuts.

On the right - Bolts for rear sandboxes with Nord-Lock washers.

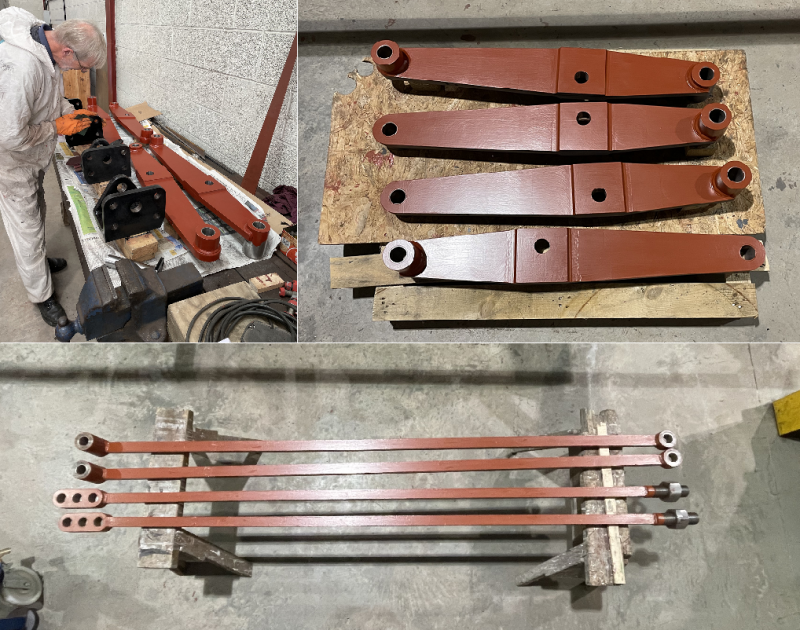

Moving towards the goal of a rolling chassis, we have fitted the spring hangers on the frame.

We have taken delivery of the completed sandboxes.

Thanks to the success of the 'Put the brakes on' fund we have purchased the components for the brake gear: brackets, hangers, shafts, rods, shaft cranks, levers, turnbuckles, hanger carriers and pins.

We spent many cold hours fitting the main brake shaft hangers, brake lever, brake shaft small cranks, brake hanger carriers and turnbuckles.

We then went on to test fit the brake hangers, brake rods and brake shafts.

We have been sent some pictures of the rear sandboxes been made.

We hope to have the completed items back at the unit for out first open day of the year on Saturday 5th March.

We have received delivery of more components for the brakes. Brake hangers, brake rods and turnbuckles.

Again, many thanks to John, who seems to spend every Saturday painting components. Even when the unit is on the cold side!

A small but crucial delivery has arrived. Believe it or not there is over £1,000 here!

These are the bolts to fix the following components to the frame: -

Main Bracket Shaft Brackets, now fully painted.

Spring Hanger Brackets

Brake Hanger Carriers

John has spent many hours painting the Main Brake Shaft; red oxide, grey undercoat and final coats of signal red and gloss black. These will be fitted soon. We have also taken delivery of the Brake Hanger Carriers.

While we still have the 'warmer' weather, we are painting as much as we can. John has out done himself by going green. We will have to wait until next year to do the lining.

The first parts for the brakes have arrived at the unit. Here we have machined components and then fully assembled main brake shaft. The white residue is from the NDT.

We still need contributions to help us complete this fund. Please click this link and download the leaflet (Click Here) or go to the Construction Funding page.

I am very please to say we have taken delivery of the Crosshead Bodies. These look truly stunning in real life. Come to our opens day for a look.

These were purchased with money donated to the 'Cash for Crosshead' fund. A big thank you to everyone who helped. There is still a bit of work that needs doing to these, but the are a major component of the motion and another big step forward.

Thanks to uptake of the 'Put the brakes on' fund, we are please to say we have placed orders for some of the brake components. See if you can work out what these pieces are.

There are still many other parts required. Go to the Construction Funding page and help us complete this part of the build by donating to the fund.

It has taken a while, thanks to Covid19, but we have now received the forged and machined pistons, thank you to Arthur Stephenson (Eng) Ltd. They look better in real life.

Thanks again to everyone who contributed to the 'Piston Plea'. You have help us complete another big step in completion of the build. We are now working on the brake components, go to the construction funding page to see how to help us with the 'Put the brakes on' fund.

The visage of various components has changed somewhat with the application of grey primer.

Front wheel-set, front sandbox/splashers and piano cover.

While the trailing wheel-set is away been assembled. John has taken the opportunity to give the front wheel-set a fresh lick of paint.

On hopefully the last cold weekend of the year, fuelled by many cups of hot tea, Ian Matthews and myself removed the temporary bolts and fitted the permanent bolts in the rear buffer beam.

Once they were fitted, 24 in total, we did a bit of final fettling with the grinder.

The buffers were dropped off at NYMR just before Christmas. They were then stripped to give then a check over.

Thankfully, other than a bit of surface rust, they were in good conditions. They were then rebuilt and given a fresh coat of vermillion paint. Thanks to Kelvin for the work and the photographs.

It has been a difficult year, so it's nice to bring some good news. As you will be aware the design and manufacture of the crankaxle has been a long and difficult process but, following a technical meeting with Ricardo Rail, we now have a clear path to achieve certification. We have agreed to a more frequent inspection regime, not a bad thing in reality, and will need to pull together a risk assessment justification case. Many thanks to Nigel Wright, one of our supporters, for help with the discussion and a better understanding of metallugy.

The crankaxle, here receiving its final machining, has now been shipped to South Devon Rail.

The two trailing wheels and tyres have been collected from the unit and shipped to SDR for final assembly. However, when they were received a problem came to light with the manufacturing of one of the wheels. Thankfully, Boro' Foundry offered to manufacture another one free of charge; many thanks to them. We dug out the original pattern, gave it a fresh coat of paint and shipped that to them.

We are now in the queue to have the wheel-set assembled and will it have back in the unit in the new year. We can then move onto achieving a 'rolling chassis'.

................................................................................................................................................

Obviously, this has been a difficult year and while work on the build has been somewhat delayed, we have taken the opportunity to paint the frames and a number of components. Mike Wood, our chairman, with help from myself and John Askwith have spend in excess of 350 hours sanding, stripping, painting, resanding and repainting. The inside of the frames alone have had 8 coats of paint.

The overall result is much improved.

We have also removed the buffers to have them overhauled.

They have been 'tided-up' prior to being sent to NYMR for assessment.

................................................................................................................................................

While the main bodies of Crossheads are being fabricated, we have just received a couple of components parts. Gudgeon pins and their oil boxes.

................................................................................................................................................

A small, but vital, set of components has just arrived. Spring pins, spring link pins and axle-box pins.

................................................................................................................................................

Work continues on the project as best we can. Please see below a photograph of the pistons at Stephenson Engineering. They have been forged and machining has started. We have sent the piston rods to them to ensure the correct fit.

................................................................................................................................................

Spring Links and Hanger Bolts.

Moving on from the spring hangers, we have just taken delivery of the Spring Links and Spring Hanger Links. We still need a few pins, but this is another step closer to getting the locomotive on it's wheels.

................................................................................................................................................

Piston Rods.

Thanks to contributions to the Piston Plea (see fund raising page) we have just taken delivery of the machining piston rods.

As you can see in the news section, you will read that we have now ordered the pistons.

................................................................................................................................................

Main Springs Hangers.

These nice shiny pieces, that we have just received, are the Main Spring Hangers.

We have gone out to quotation for the other components required to complete the set; spring link, threaded spring bolt, spring washer and various nuts.

................................................................................................................................................

Main Springs.

Moving on to achieving a rolling chassis. We have taken delivery of the four main springs, which we will require for mounting the leading and trailing axles. The spring hangers have also been ordered, but we still need various pins and the treaded adjusters.

................................................................................................................................................

Coupling Rods.

The fully machined Coupling Rods have now arrived at the unit. The work was undertaken by Stephenson Engineering. We still require the coupling rod bushes.

................................................................................................................................................

Front Sandboxes / Splashers.

ID Howitt has done a fantastic job of constructing the Front Sandboxes / Splashers. We took delivery late June. These are a nice addition to the components we are collecting in the unit.

................................................................................................................................................

Fitting the Motion Bracket.

The Motion Bracket has now been correctly positioned within the frame. This require very careful measurements and the use of the age old technique of lining up a 'piano wire' perfectly down the bore of the cylinders. This ensures that the motion bracket placement is perfect and the slide bars will be parallel to the cylinders.

If you look close you can see the piano wire.

................................................................................................................................................

Tank Support Brackets.

The tank support brackets have now been fabricated and have been fitted to the frames.

................................................................................................................................................

Coupling Rods.

The machining has started started on the Coupling Rods. There is a lot of material to remove! We should have the finished pieces back in the unit in May.

................................................................................................................................................

Motion Bracket.

Work continues on the fitting of the motion bracket. The spindle guide has been installed. After final machining Ian Howitt will be fitting the bracket over the next month.

The components for the Tank Support Brackets have been cut be Franklyn Steel and will be shipped to North View for fabricating in the brackets. We have asked Ian Howitt to fit these when he installs the motion bracket.

................................................................................................................................................

Rear Cylinder Covers and Stuffing Boxes.

With the Motion Bracket planned for fitting in January, we have taken delivery of the newly manufacturered and machined rear cylinder covers and the stuffing boxes. This will need to be fitted prior to installation on the motion bracket. The slide bars fit on top of the stuffing boxes and the motion bracket. We took delivery of the slide bars earlier in the year.

................................................................................................................................................

Coupling Rod blanks.

The latest addition to the parts at the unit are the coupling rod blanks. These were forged by Somers Forge, Halesowen and coming in at a hefty 381 kg each, or nearly 60 stone a piece. A lot of the material will be removed when they are machined.

...............................................................................................................................................

Angle Irons and Gusset Plates.

For those who could not make our annual conference, you will not have seen the latest progress.

The Angle Irons and Gusset Plates are now in place, awaiting the Tank Supports and Running Boards.

Current work in progress:-

The crank axle has been forged and is currently undergoing testing and machining. Plans have been produced for the running boards, tank support brackets and coupling rods and 2018 should see great progress with these, as well as the assembly of the trailing wheelset.

We have currently completed:-

The smoke box together with door and chimney have been manufactured and are fitted to the frames

The main frames:- they are assembled together with all the major castings, cylinder blocks, drag box, bogie support and horne guides.

The frames are mounted on the bogie which is completed to main line standards

The all welded boiler is completely finished except for hydraulic testing.

The rear of the cab incorporating the bunker and rear water tank.

The leading wheelset.

The wheels and tyres for the crank axe are finished and are in our unit at Shildon awaiting the completion of the crank axle.

We have established a separate fund to raise money for the crank axle- the only major component needed to complete the rolling chassis. We have also established another separate fund to raise money for the locomotive's motion components.

We have collected over 130 of the original drawings for the locomotive which will ensure accuracy and authenticity to the completed locomotive.

Some compromises have been made to comply with modern regulations such as the use of an all-welded boiler rather than the traditional riveted construction; these changes have been inspected and approved and are registered at Lloyds for insurance purposes. Others such as moving the Westinghouse pump from the cab to the front of the tank, modifications to the bogie and the replacement of wooden buffer beams by steel, have been done for expedience and to improve the engineering qualities of the finished locomotive. None of these changes will detract from the external appearance of such a beautiful piece of Victorian design; in fact some of these changes were also implemented by the LNER for the same reason.

In addition to the above major components the company also have many smaller components, safety valves, Westinghouse pump, brake gear and reconditioned Ross pop safety valves, bell type whistle, Davies & Metcalfe vacuum brake ejector valve and air cylinder, as well as other vital components, including AWS equipment have been purchased. Other component acquitions include a fully reconditioned eight port Wakefield lubricator, with a second six port to hand; a pair of Gresham & Craven lifting injectors, as originally fitted to the locomotive have been purchased and both are fully reconditioned.

In February 2009 we took the major decision to build the locomotive to main line standards so that it can obtain main line certification status. This significantly increases the final building cost but will help to maximise and secure our income for the future; with main line certification this locomotive will be capable undertaking short to medium length working on secondary lines.